Profile Projectors: Specifications, Features, Applications, and Buying Tips

Profile projectors, also known as optical comparators, are precision instruments used to inspect and measure the dimensions and geometry of components. They project an enlarged silhouette of a part onto a screen, allowing operators to compare it against prescribed limits. This non-contact method is ideal for delicate components that cannot withstand physical touch, ensuring accurate measurements without causing damage.

Specifications of Profile Projectors

Profile projectors vary in specifications based on their design and intended use. Key specifications include:

- Measuring Range: The area over which measurements can be taken. For example, some profile projectors offer an XY measuring range of 100 x 100 mm.

- Screen Size: The diameter of the projection screen, which can range from 200 mm to 300 mm, affecting the size of the part that can be inspected.

- Magnification: Determines the level of detail visible on the screen. Higher magnification is suitable for inspecting fine details.

- Illumination Type: LED or halogen lighting systems are commonly used, with LED offering energy efficiency and longer lifespan.

- Stage Travel: The movement range of the stage in the X, Y, and Z axes, which affects the ease of positioning the part.

Features of Profile Projectors

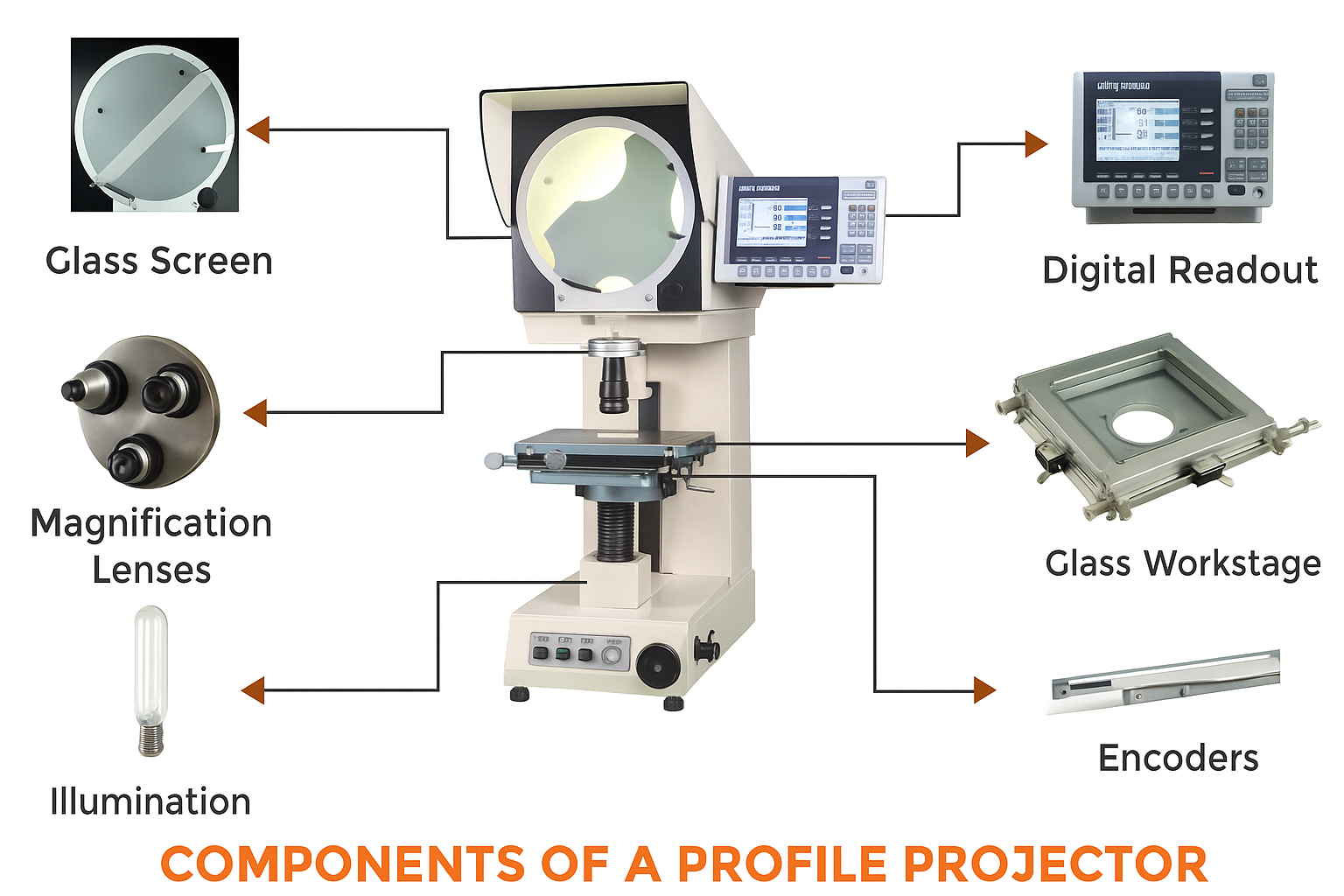

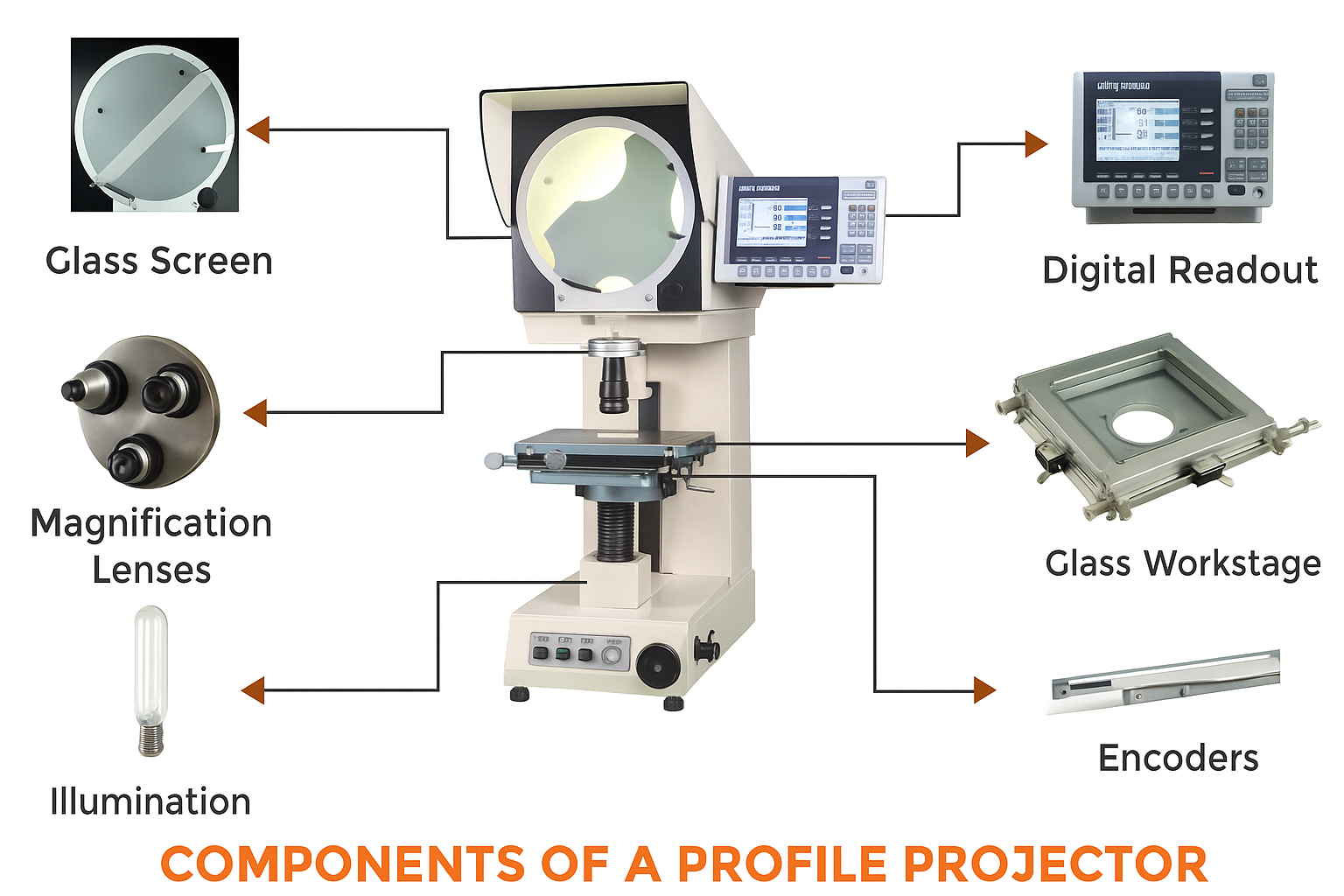

Modern profile projectors come equipped with various features to enhance measurement accuracy and ease of use:

- Digital Readouts: Provide precise measurements and reduce human error.

- Rotatable Screens: Allow for the alignment of parts at different angles for comprehensive inspection.

- Surface Illumination: Helps in assessing surface finishes and detecting surface defects.

- Data Processing Software: Facilitates advanced analysis and documentation of measurements.

- Non-Contact Measurement: Ensures that delicate components are not damaged during inspection.

Applications of Profile Projectors

Profile projectors are utilized across various industries for precise measurement and inspection:

- Automotive Industry: Inspecting components like gears, cams, and molds to ensure they meet stringent quality standards.

- Aerospace and Defense: Measuring complex parts such as turbine blades and missile components to maintain safety and performance.

- Medical Device Manufacturing: Verifying the dimensions of implants and surgical instruments to ensure patient safety.

- Electronics Manufacturing: Inspecting printed circuit boards (PCBs) and connectors for accuracy and reliability.

- Reverse Engineering: Creating digital models of existing components when original designs are unavailable.

Buying Guide for Profile Projectors

When selecting a profile projector, consider the following factors to ensure it meets your specific needs:

- Measurement Range: Choose a projector with a measuring range suitable for the size of the parts you intend to inspect.

- Magnification: Higher magnification is essential for inspecting fine details but may reduce the field of view.

- Screen Size and Illumination: Ensure the screen size is adequate for your parts and that the illumination system provides clear visibility.

- Stage Movement: Check the stage's travel range and ease of movement to facilitate smooth positioning of parts.

- Software Integration: Consider models with data processing software for advanced analysis and documentation.

- Budget: Balance the features you require with your budget constraints.

Some profile projectors offer LED illumination, XY stage movement, and magnifications suitable for a wide range of applications, making them versatile tools in precision inspection.

Profile projectors are indispensable tools in precision measurement and quality control across multiple industries. By understanding their specifications, features, applications, and considering key factors during the purchasing process, you can select a profile projector that best fits your requirements. Investing in a high-quality profile projector ensures accurate measurements and contributes to the overall quality and reliability of your products.