In the high-precision world of automotive and aerospace engineering, every micron matters. The difference between a perfectly aligned shaft and one with minor eccentricity can determine performance, safety, and longevity. That’s where the Roundness Measuring Tester by RB Metrology stands as a cornerstone of dimensional accuracy which merges advanced mechanics, optics, and data interpretation into one seamless testing solution.

As an Exporter and Wholesale Supplier of metrology and testing instruments, RB Metrology delivers world-class tools engineered for perfectionists, those who understand that precision isn’t an option, but an obligation.

Roundness, though seemingly simple, is one of the most complex geometric properties to measure accurately. In the real world, no component is ever perfectly circular. Every machined part, from bearings to shafts, has micro-level deviations.

The Roundness Measuring Tester quantifies these deviations with incredible precision, analyzing the circular form errors that can affect performance. Whether in rotating components of an aircraft turbine or a car engine crankshaft, even the slightest deviation can lead to imbalance, vibration, or premature wear.

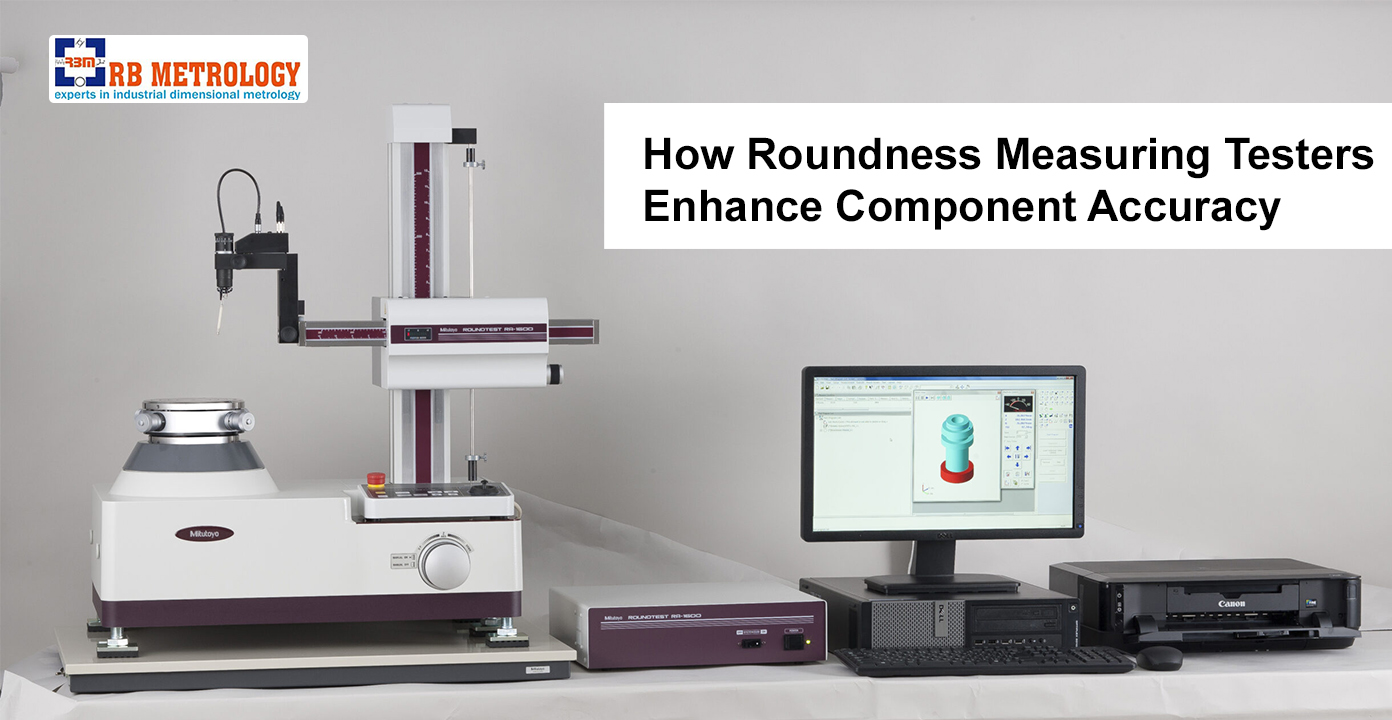

Through optical sensors, high-resolution encoders, and computer-driven data interpretation, the RB Metrology Roundness Measuring Tester transforms these measurements into actionable insights, ensuring that each component matches the exact engineering standard required.

Automotive manufacturers deal with high-speed rotational assemblies like pistons, gears, shafts, and bearings where the margin for error is extremely small. Imperfect roundness in any of these parts can result in:

By implementing roundness testing as part of quality assurance, automotive producers can validate every part before assembly. The RB Metrology Roundness Measuring Tester captures sub-micron variations, generating precise digital data that helps maintain consistency across production batches.

The tester’s non-contact optical measurement and high-speed rotational table ensure that even delicate components can be analyzed without deformation, preserving their structural integrity.

In aerospace applications, accuracy is mission-critical. Jet engines, control actuators, and turbine components demand flawless geometry for stable operation under extreme conditions.

Aerospace engineers rely on Roundness Measuring Testers to:

RB Metrology’s tester offers high-resolution spindle rotation, precision probe positioning, and data repeatability that align with the stringent standards of aerospace quality control. It ensures that every surface contour, even invisible to the naked eye, is measured, mapped, and recorded for traceable inspection reports.

The 2D Roundness Measuring Tester from RB Metrology is engineered to deliver both speed and accuracy in measurement. Its design integrates:

This machine’s modular architecture allows calibration for different component geometries from circular shafts to complex turbine hubs. The inbuilt error-compensation algorithms correct any minute distortions, making it a benchmark of metrological accuracy.

What differentiates RB Metrology in the global testing equipment market is its focus on engineering precision backed by field practicality. Every Roundness Measuring Tester undergoes multi-stage inspection, ensuring mechanical stability, temperature consistency, and repeatability under continuous operation.

As a Wholesaler and Exporter, RB Metrology supplies testing instruments to industries such as:

The company’s calibration processes align with ISO 9001 and international metrology standards, ensuring each machine performs reliably under demanding conditions.

Modern production floors rely heavily on digital integration. Roundness Measuring Tester supports seamless connectivity with CMM software platforms, SPC databases, and ERP quality modules.

This integration enables:

Such features help manufacturers transition from manual inspection to smart quality ecosystems, driving efficiency and reducing human error in dimensional validation.

While roundness measures geometric accuracy, surface finish defines smoothness. The RB Metrology Roundness Measuring Tester can be paired with surface roughness testers to provide a complete form analysis.

Together, they evaluate:

This comprehensive analysis ensures parts not only appear geometrically sound but also perform smoothly under operational stress.

By preventing production errors and ensuring repeatable precision, roundness testing reduces material waste and energy use. Each perfectly aligned component means fewer reworks, less scrap, and more efficient machine operation, supporting both economic and environmental sustainability goals.

RB Metrology, as a responsible Exporter and Wholesale Supplier, emphasizes sustainability in both design and supply practices. Machines are built to last, easy to calibrate, and require minimal maintenance.

In industries where precision is power, the Roundness Measuring Tester by RB Metrology stands as a benchmark of reliability and engineering excellence. Whether it’s the flawless curvature of an automotive piston or the micro-level geometry of an aerospace turbine blade, RB Metrology ensures every measurement counts.

By combining advanced technology, rigorous specifications, and real-world performance, RB Metrology helps manufacturers worldwide achieve accuracy that sets new industry standards.

RB Metrology is a reputed Manufacturer, Exporter, and Wholesale Supplier of advanced testing and metrology equipment, serving industrial clients across India and international markets. Known for their commitment to precision, quality, and innovation, they deliver a complete range of dimensional measurement instruments, from Video Measuring Machines to Roundness Testers, ensuring every client achieves uncompromised quality assurance.

1. Can this tester handle both small and large components?

Yes. The machine supports a wide measurement range (up to 350 mm in diameter), making it suitable for small precision parts and large industrial components alike.

2. What kind of output or data does the tester provide?

The tester delivers graphical analysis, digital roundness error values, polar plots, and form deviation charts, which can be exported through USB or Ethernet connectivity for quality documentation.

3. Is calibration required frequently?

Routine calibration ensures accuracy, but RB Metrology’s instruments are engineered for long-term stability, minimizing the need for frequent recalibration.

4. Does the tester support integration with other quality systems?

Yes. It can be seamlessly integrated with CMM software, SPC systems, and ERP modules, allowing automated data collection and comprehensive process monitoring.

5. How does the tester ensure operator safety and ease of use?

The tester includes automated spindle control, real-time measurement display, and stable platform design, reducing human error while maintaining operational safety.

6. Is RB Metrology an Exporter or a local supplier?

RB Metrology is a reputed Exporter, Wholesaler, and Wholesale Supplier of metrology and testing instruments, providing reliable quality solutions to industries worldwide.