Advantages and Disadvantages of the Profile Projector

A profile projector, also known as an optical comparator, is a widely used measuring instrument in manufacturing and engineering. It magnifies the image of a component onto a screen, allowing precise inspection of dimensions, angles, and geometrical profiles without direct contact. This tool is commonly used in industries such as automotive, aerospace, mechanical engineering, and precision tooling. Understanding its advantages and disadvantages helps professionals determine its suitability for specific tasks.

What is a Profile Projector?

A profile projector is an optical device that projects the silhouette or profile of an object onto a large screen. Using a combination of lenses and light, it magnifies the object’s profile, allowing accurate measurement of small dimensions, contours, angles, and threads. Profile projectors are commonly used for quality control and inspection of machined components, especially when high precision is required.

Key components include:

- Projection lens: Magnifies the object.

- Screen: Displays the magnified profile for measurement.

- Stage/table: Holds the object and allows movement for alignment.

- Lighting system: Illuminates the object from above (vertical) or below (horizontal).

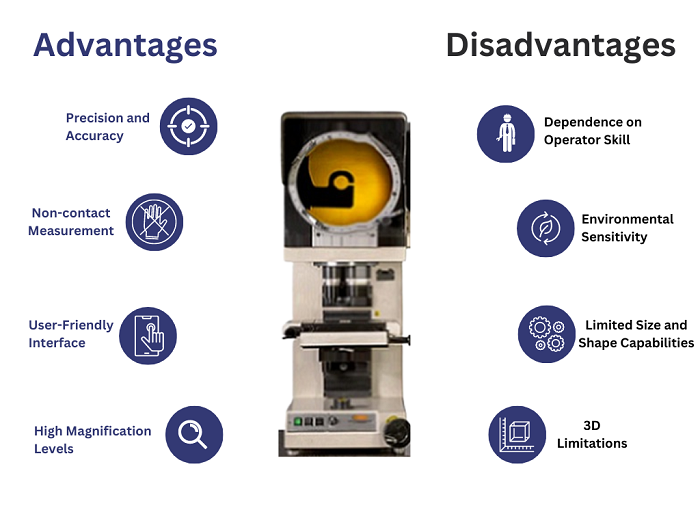

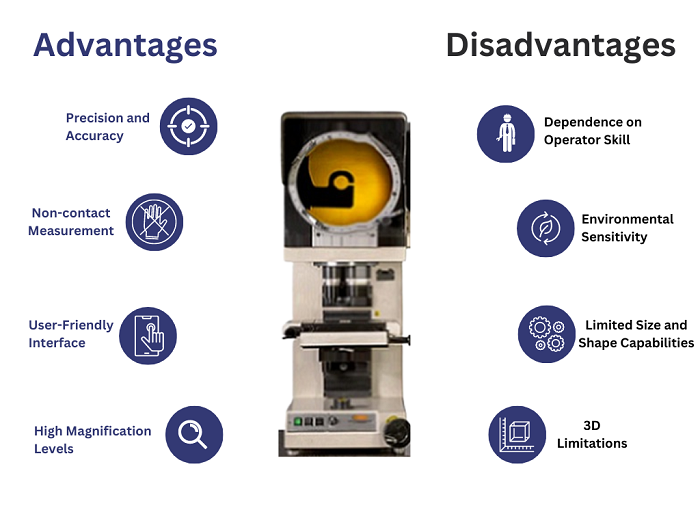

Advantages of the Profile Projector

- High Accuracy and Precision

Profile projectors allow precise measurement of complex shapes, angles, and contours, often with an accuracy of up to 0.01 mm, depending on magnification and calibration. This makes them ideal for inspecting precision-engineered components.

- Non-Contact Measurement

Since measurements are optical, there is no physical contact with the component. This prevents damage to delicate parts, such as thin sheets, soft metals, or intricate components.

- Ease of Inspection of Small Parts

Small components that are difficult to measure with vernier calipers or micrometers can be easily analyzed. Magnification allows operators to see fine details clearly.

- Versatility in Measurements

Profile projectors can measure angles, radii, diameters, thread profiles, and contours. They can also be used to compare manufactured parts with engineering drawings for conformity.

- Time Efficiency

Multiple measurements can be taken quickly without extensive setups, making it a valuable tool in mass production quality control.

- Documentation and Comparison

Many modern profile projectors allow digital measurement capture or overlay comparison with CAD drawings, which improves reporting, traceability, and error detection.

Disadvantages of the Profile Projector

- High Initial Cost

Profile projectors are expensive compared to simple measuring tools like vernier calipers or micrometers. The cost of purchase and maintenance can be significant, particularly for high-precision models.

- Limited to 2D Measurement

A standard profile projector only measures two-dimensional features. Depth, thickness, or internal geometries cannot be inspected without additional equipment.

- Dependence on Operator Skill

Accurate measurements require careful alignment of the part and correct interpretation of magnified images. Operator error or inexperience can lead to inaccurate results.

- Bulky and Requires Space

Traditional optical comparators are relatively large and need stable surfaces to avoid vibrations, making them less suitable for small or crowded workshops.

- Lighting Sensitivity

Inadequate lighting or incorrect positioning can distort the image, affecting measurement accuracy. Clean and consistent illumination is essential.

- Maintenance and Calibration

Regular calibration is required to maintain accuracy. Dust, scratches, or misalignment of optical components can affect the performance and reliability of measurements.

- Inspection of gears, cams, and threads.

- Quality control of precision components in automotive and aerospace industries.

- Checking engineered parts against CAD drawings or templates.

- Measuring small holes, slots, and contours.

- Comparative inspection in mass production environments.

The profile projector is a highly valuable tool in precision measurement, offering accuracy, versatility, and the ability to inspect delicate components without contact. However, its limitations—such as high cost, reliance on operator skill, and restriction to 2D measurement—must be considered when choosing the right inspection method.

For manufacturers, engineers, and quality control professionals, understanding the advantages and disadvantages of profile projectors ensures efficient use of resources and accurate product inspection.