Profile projectors are essential tools in modern manufacturing, ensuring precise inspection and measurement of components. They allow manufacturers to verify dimensions, angles, and shapes without physically touching the part, reducing errors and enhancing product reliability.

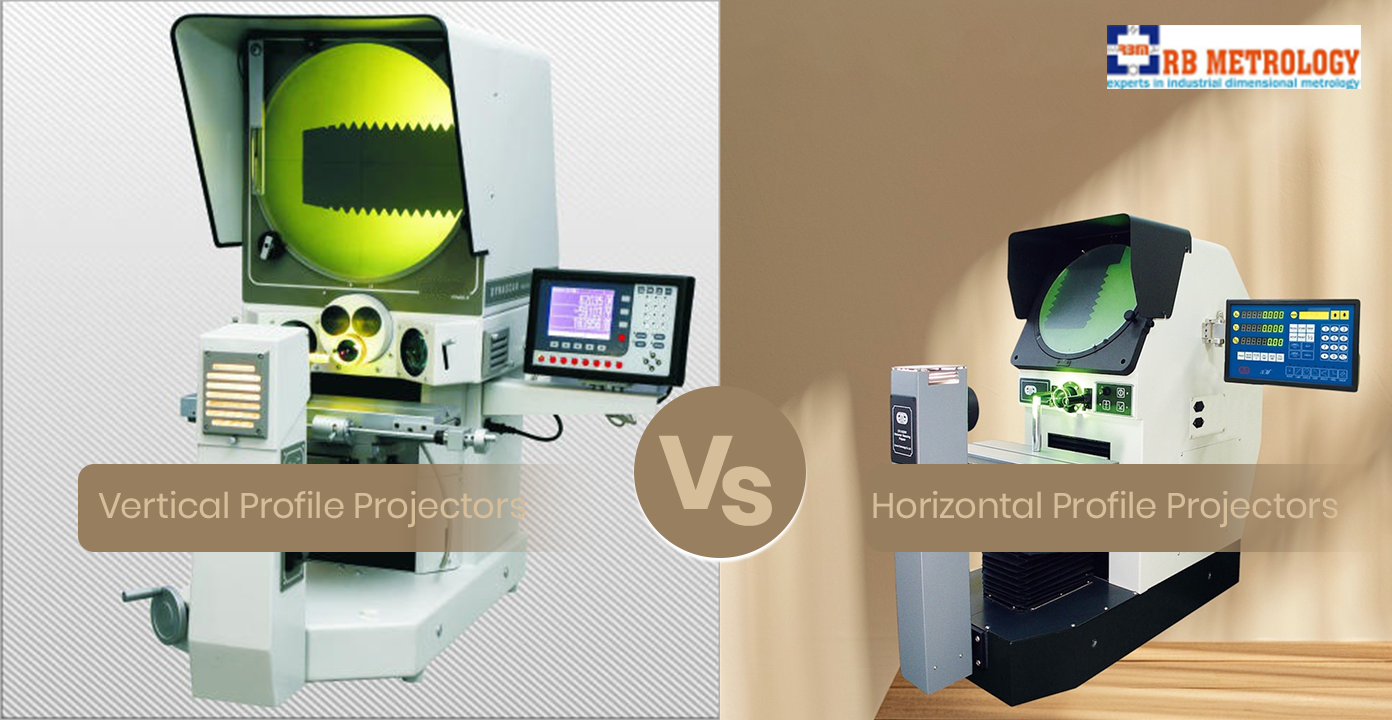

By using profile projectors, industries can maintain high-quality standards, ensure parts fit perfectly in assemblies, and minimize rework.Both vertical and horizontal profile projectors are widely used, catering to different component sizes and inspection needs.

RB Metrology is a trusted supplier, providing precision measurement instruments that meet industry standards and reliability expectations.

A vertical profile projector is designed to project the profile of a component onto a vertical screen for measurement. The part is placed on the horizontal stage, and light is cast to create a magnified image of its profile on the screen.

Applications: Ideal for small to medium-sized components such as gears, shafts, and precision parts used in electronics or machinery.

Advantages:

A horizontal profile projector projects the profile of a component onto a horizontal surface. The light source and projection system are arranged to accommodate heavier or larger components.

Applications: Suitable for large industrial parts, automotive components, or machinery assemblies requiring accurate measurement.

Advantages:

| Feature | Vertical Profile Projector | Horizontal Profile Projector |

|---|---|---|

| Orientation | Projects profiles onto a vertical screen, part placed on horizontal stage | Projects profiles onto a horizontal surface, part placed vertically or horizontally |

| Parts Handled | Small to medium-sized components such as gears, shafts, and precision instruments | Larger or heavier components, including automotive parts and industrial machinery components |

| Measurement Accuracy | High precision for fine details and small tolerances | Very accurate for larger parts; maintains accuracy over longer distances |

| Space Requirement | Compact, requires less floor space | Larger footprint due to horizontal layout and heavier parts |

| Stage Flexibility | Suitable for lightweight stages; limited travel range | Supports heavy-duty stages with larger travel for bulky components |

| Lighting Method | Typically transmitted or reflected light for detailed imaging | Can use both transmitted and reflected light; accommodates deeper shadows for large parts |

| Magnification Range | High magnification, ideal for micro components | Wide magnification range, suitable for large profiles and assemblies |

| Inspection Speed | Quick for batch inspection of small parts | Efficient for large, complex components but slightly slower setup |

| Repeatability | Excellent repeatability for small, precision parts | High repeatability for industrial-scale measurements |

| Ease of Handling | Easy to place and reposition small parts | Requires fixtures or supports for heavy parts; ergonomic considerations |

Vertical and horizontal profile projectors both offer precise dimensional measurement, but their capabilities vary slightly based on orientation and design:

Profile projectors are widely used across sectors, with vertical and horizontal models optimized for specific tasks:

Vertical projectors are ideal for electronic components, micro-gears, and tiny mechanical parts where high magnification and precise measurements are critical.

Understanding accuracy and operational performance helps in selecting the right projector for the job:

Selecting the appropriate profile projector is critical for accurate measurements and efficient workflow. Several factors should be considered:

Based on part size and complexity: For small, intricate components like micro-gears, electronics, and precision tooling, vertical projectors are ideal due to their compact design and high magnification. For larger or heavier parts such as engine components, molds, or structural assemblies, horizontal projectors offer better support and measurement range.

Measurement accuracy requirements: If parts require micron-level precision or tight tolerances, vertical projectors provide higher resolution and repeatability. For applications with moderate tolerances, horizontal projectors maintain reliable accuracy while accommodating larger dimensions.

Production volume and usage frequency: For high-volume batch inspections, projectors with automated or semi-automated features can save time and ensure consistency. Single-part or occasional measurements can be efficiently handled with standard models.

Expert advice from RB Metrology: Consulting with professionals ensures the selected projector matches industry requirements, workflow, and part specifications, reducing errors and improving quality control outcomes.

Proper maintenance and operation are key to preserving accuracy and extending the lifespan of profile projectors:

RB Metrology is a trusted name for industrial measurement solutions, offering:

Wide range of vertical and horizontal profile projectors suitable for diverse applications, from micro-components to large mechanical parts. Their instruments deliver high-accuracy measurements essential for automotive, aerospace, electronics, and precision engineering industries.

RB Metrology provides competitive pricing and bulk supply options, ensuring cost-effective procurement for manufacturers and inspection labs. Reliable technical support, installation guidance, and after-sales service help clients maintain productivity and measurement accuracy over the long term.